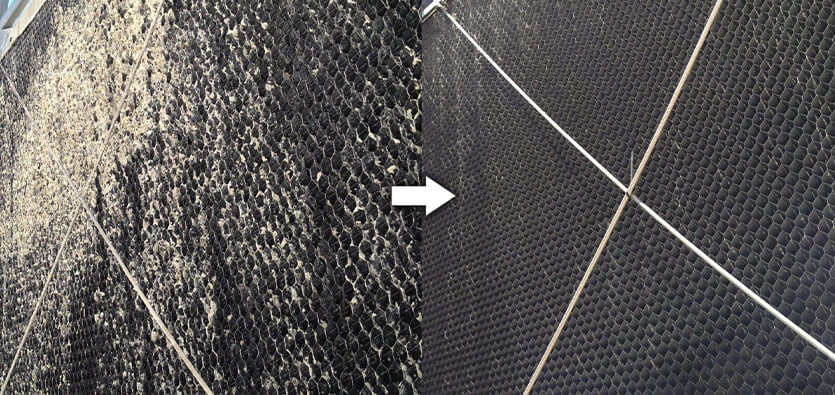

When hard water scale accumulates in your cooling tower system, the system needs to work harder to draw extra energy. The increased energy consumption impacts the longevity of the system and prevents it from achieving maximum capacity. Like other dirt and debris, scale needs to be cleaned and several industrial cleaners can help you to do it efficiently.

When water is evaporated or heated, solid matter called scale is left behind. This scale can severely impact the efficiency of your water cooling systems. Scale forms thick deposits on the heat transfer area decreasing heat transfer, reducing water flow, and causing high head pressure.

The presence of scale also makes the system’s processor work harder. Aside from pressuring the processor, scale formation also lowers the lifespan of the system. Therefore it is important to clean the cooling system from scale after regular intervals. This blog explains the methods you can use to descale your cooling tower to enhance its efficiency and life expectancy.

Descaling Chemical Options

You can use various descaling chemicals for this purpose. Various specialized descaling chemicals and cleaning products are available in the market. The chemicals generally fall into the following three categories.

- Hydrochloric acid

- Sulfamic acid

- Methane sulfonic acid

How To Clean The System

The amount of chemical required to clean the cooling system will depend on the scale and type of chemical used. For any specific treatment guideline, it is best to refer to the label on the product. In general, it is better to only use three doses of acid water. Moreover, it is advised that you get the descaling process done by professionals, as they will know how to handle the industrial cleaners correctly.

Read More: WHY DO YOU NEED EXPERTS TO HANDLE INDUSTRIAL CLEANING PRODUCTS?

Preparing The System For Descaling

Before descaling, make sure to check and clean the system’s nozzles or water distribution holes. Also, check and drain any sumps, refill it with fresh water, and start the pump again. Make sure that you stop the bleeding if there is any. All these steps will reduce the amount of descaling treatment required by your cooling system.

Descaling Process

The descaling process and use of industrial cleaners and acids should always be supervised and regulated. Generally, the acid solution should rotate in the system for hours, depending on the amount of scale present. However, it is necessary to make sure that the acid does not stay longer in the system than necessary. Especially, make sure that hydrochloric acid or methane sulfonic acid does not remain in the system for more than six hours.

If you choose a pH indicator treatment, the color of the acid coming out of the condenser will indicate the level to which the equipment has been cleaned.

Cleaning Tips For Descaling

Irrespective of the acid you use, here are some cleaning tips you should follow;

- Always make your workers wear protective kits such as gloves, eye protection, and a respirator. Make sure descaling solutions never come in contact with your skin, eyes, etc.

- Higher temperatures, higher circulation speed, and strong solutions can increase the speed of descaling. However, you should make sure that the descaling is done in a safe environment with lots of ventilation.

- Make sure you vent any close space to avoid the build-up of gases.

- Pay attention to the recirculating water containing acid so it does not become airborne.

- After you are finished cleaning, make sure to thoroughly flush out the neutralized acid out of the system according to your local regulations.

- Sometimes, metal has corroded and was held by scale or other deposits. So, after cleaning it is best to check the system for leaks.

About Us

Sunrise industrial cleaners is an Edmonton-based company, specializing in providing quality industrial-grade cleaning products to its customers. Our traditional one-on-one sales and customer service provide our clients with ease to choose the products that best suit their needs. Contact us today and get your compatible and best-performing industrial cleaners.